Intelligent Wear Monitoring of Micro Drill Bit Automatic Regrinding In-Line Systems

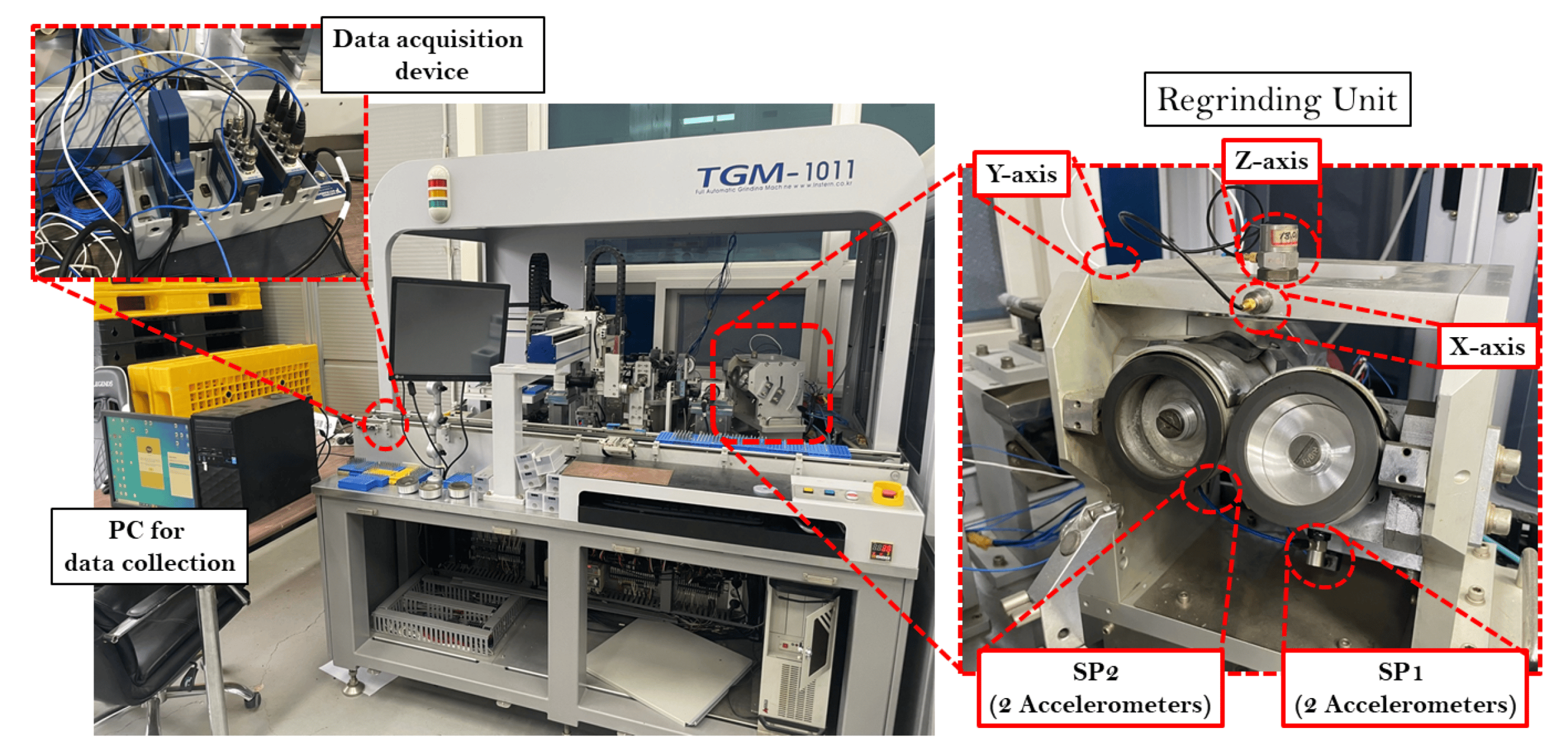

Vibration signals from the equipment’s frame and high-speed grinding wheels are analyzed to capture the health status of the grinding wheel. A spectral isolation technique is employed as a preprocessing step to retain only the critical spectral segments, thereby enhancing diagnostic accuracy while reducing computational costs.

Artificial intelligence-based models, including one-dimensional convolutional neural networks (1D-CNN) and multi-layer perceptron (MLP) neural networks, are used to learn and classify the discriminant spectral features. Experimental results indicate that spectral isolation improves diagnostic accuracy by 4.6% with 1D-CNNs and by 7.5% with MLPs, while also reducing computational costs by approximately 1.3% and 5.71%, respectively.

Grants and Sponsors

- Grand Information Technology Research support (IITP-2020-2020-0-01612) provided by the MSIT (Ministry of Science and ICT) South Korea (2020 -2021)

- Korean National Research Foundation of Korea (NRF) grant (No. NRF-2019R1I1A3A01063935) provided by the MSIT (Ministry of Science and ICT) South Korea (2019).

- Instern Co., Ltd

Journal Publication from the project

U. E. Akpudo & Hur, J. W. (2022). Exploring the Efficiencies of Spectral Isolation for Intelligent Wear Monitoring of Micro Drill Bit Automatic Regrinding In-Line Systems. Algorithms, 15(6), 194.