FMECA and Intelligent Fault Diagnostics of Gear Pumps

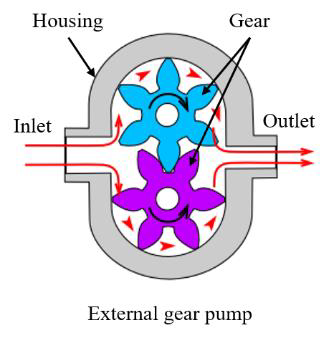

Accurate condition monitoring of industrial cyber-physical systems/components demands the use of reliable failure modes, effects, and criticality analysis (FMECA), fault detection and isolation (FD&I), and the remaining useful life (RUL) estimation methodologies. Gear pumps often face wear issues in the bearings, housing, and/or the gears (particularly for external gear pumps)

Accurate condition monitoring of industrial cyber-physical systems/components demands the use of reliable failure modes, effects, and criticality analysis (FMECA), fault detection and isolation (FD&I), and the remaining useful life (RUL) estimation methodologies. Gear pumps often face wear issues in the bearings, housing, and/or the gears (particularly for external gear pumps)

The major objectives of the project are:

- To conduct FMECA on BESCO’s AP3.5/100 external gear pumps

- To design and simulate test beds for multi-failure mode and run-to-failure tests for fault diagnosis and prognosis respectively for the pumps.

- To extract vibrational, thermal, and pressure responses (data) for developing AI-based models for intelligent condition monitoring and decision-making.

- To evaluate the performance of the developed models on real industrial equipment for validation.

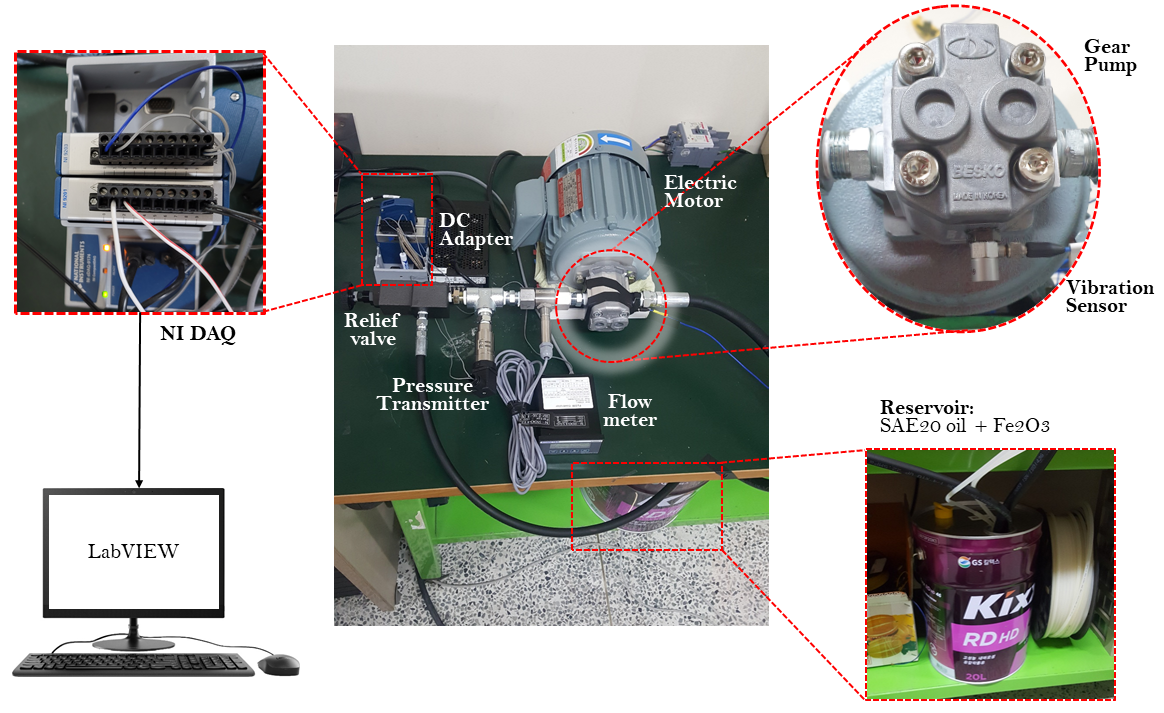

I and my team discovered different condition monitoring methodologies for gear pumps. I explored these existing condition monitoring concepts from distinct analytical researches, as well as their limitations/gaps and drawbacks. I reviewed these design concepts and drawbacks, afterwards I proposed a vibration monitoring approach that is fundamentally dependent on the exploitation of mel-frequency cepstral coefficients from the vibration signals. The AP3.5/100 external gear pump is powered by a 3-phase induction motor (rated 220 V, 0.75 KW, 60 Hz, 1720 rpm) and connected to a relief valve that controls the fluid flow to produce stable pump pressure (above 50-100 Bar). From observation and related works, the variables- flowrate, vibration, and pressure change as operating condition changes for both pump types and so can reflect degradation/failure modes.

Grants

- Grand Information Technology Research support (IITP-2020-2020-0-01612) provided by the MSIT (Ministry of Science and ICT) South Korea (2020 -2021)

- Korean National Research Foundation of Korea (NRF) grant (No. NRF-2019R1I1A3A01063935) provided by the MSIT (Ministry of Science and ICT) South Korea (2019).

- Agency for Defense Development grant (UD180018AD) provided by the RAM Specialized Laboratory, South Korea (2019).

Journal Publication from the project

Geon-Hui Lee, U. E. Akpudo and H. Jang-Wook, “FMECA and MFCC-Based Early Wear Detection in Gear Pumps in Cost-Aware Monitoring Systems,” in Electronics, 10(23), 2939, 2021.